1. Introduction

The global transition to electric mobility is no longer limited to passenger cars. In 2025, logistics fleets — including electric light trucks, heavy-duty vehicles, and urban delivery vans — are rapidly replacing traditional fuel-powered vehicles. For logistics parks, warehousing centers, and fleet depots, building dedicated EV charging stations has shifted from being optional to being an operational necessity.

As the world moves from the “fuel-based logistics cost model” to the “electric mobility cost model,” energy becomes a controllable business variable rather than an unpredictable expense. For logistics companies managing dozens or hundreds of vehicles, in-house EV charging infrastructure is not merely about convenience — it defines competitiveness, profitability, and sustainability.

2. Lower Operating Costs — The Core Driver Behind Fleet Electrification

The number one reason logistics enterprises are building private EV charging stations is cost control. Electricity is significantly cheaper and more predictable than fuel.

| Project | Fuel Vehicles | Electric Vehicles |

|---|---|---|

| Energy cost | High, volatile | Low, predictable |

| Per-vehicle delivery cost | High | ↓ 20%–50% |

| Night charging | Impossible | ✔ Off-peak power available |

Fleet operators can save thousands to millions of dollars annually by switching to nighttime “off-peak charging” strategies. Large-scale fleets with 50–500 vehicles can access utility discounts, negotiate electricity tariffs, and even optimize charging schedules via smart energy management systems.

For example, with a properly designed charging system, electricity costs can be reduced by up to 40%. This is a direct profitability driver — not only saving fuel expenses but also transforming energy management into a measurable ROI.

3. Fleet Depots: The Perfect Location for EV Charging Infrastructure

Unlike passenger EVs, logistics vehicles follow fixed routes and predictable schedules. They always return to base, making fleet depots and logistics parks the most logical and efficient locations for charging stations.

Typical logistics vehicle behavior:

Parked in depots at night

Regular loading/unloading schedules

Fixed routes and return cycles

These characteristics make depots ideal for:

Night charging

Mixed slow and fast charging setups

Centralized scheduling and management

A private charging facility ensures high utilization rates — the key metric for fast ROI. Unlike public charging stations that rely on unpredictable user traffic, fleet depots have guaranteed demand, maximizing efficiency and reducing payback time to 12–24 months in many cases.

4. Overcoming Range Limitations: Ensuring Operational Continuity

Electric logistics vehicles consume more energy due to heavy loads, frequent stops, and dense delivery schedules. Without an on-site charging station, drivers face multiple operational challenges:

❌ Long queues at public charging stations

❌ Charging unavailability during peak hours

❌ Delayed deliveries and missed service-level agreements (SLAs)

By contrast, self-built charging depots ensure:

Continuous operation

Guaranteed dispatch schedules

Reduced downtime

This infrastructure reliability directly affects fleet utilization, route predictability, and customer satisfaction — all vital KPIs in logistics operations.

5. Supporting Policy Compliance and Carbon Reduction Goals

Global governments are increasingly introducing policies that encourage commercial EV adoption through:

Financial subsidies and tax incentives

Free parking and license benefits

Carbon credit trading systems

Exemptions from low-emission zone restrictions

By investing in fleet-based charging infrastructure, logistics companies can access multiple layers of value:

Direct government subsidies

Carbon offset income through emissions trading

Alignment with green supply chain policies from major e-commerce and retail partners

Many cities now require logistics suppliers to meet “zero-emission delivery” targets. Owning a charging station strengthens corporate ESG performance and compliance readiness.

6. Private vs Public Charging: Why In-House Always Wins

| Item | Public Charging | In-House Charging (Fleet Depot) |

|---|---|---|

| Electricity cost | High, fixed rates | ⚡ Lower, controllable |

| Queueing | Common | None (dedicated access) |

| Eficacia | Unpredictable | Optimized via scheduling |

| Profit | Goes to third-party | 100% retained by fleet |

Private fleet charging gives companies control over cost, uptime, and reliability — critical advantages over depending on public networks.

In addition, on-site energy management enables fleets to:

Utilice dynamic load balancing

Optimize charging by vehicle priority

Schedule off-peak charging

Integre battery storage for peak shaving

This approach reduces dependency on the grid while maintaining operational flexibility.

7. Turning Charging Infrastructure into a Profit Center

A growing number of logistics parks are transforming their private charging stations into revenue-generating hubs.

Because they are usually located near industrial zones or transport corridors, they naturally attract external customers such as:

Urban delivery trucks

Ride-hailing vehicles

Private EVs

Cold-chain transporters

Heavy-duty trucks

By opening part of the charging network to the public during off-peak hours, logistics companies can:

Increase utilization

Generate additional income

Shorten ROI cycle

In many successful projects, EV charging has become a secondary revenue stream, not just a support function.

8. Photovoltaic + Energy Storage Integration: The Next Step in Cost Reduction

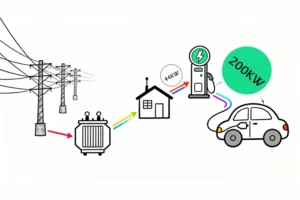

Most logistics parks have large, unused roof or canopy surfaces — perfect for solar PV installation. By combining solar generation, energy storage, and charging (known as PV + Storage + Charging integration), companies can create energy self-sufficiency.

Benefits include:

☀️ Solar canopy charging — for day operations

⚡ Warehouse rooftop PV — large-scale generation

🔋 Battery storage systems — for peak shaving and off-peak optimization

Together, these technologies enable:

Self-generated, self-consumed electricity

Grid independence and resilience

Reduced transformer upgrades

Significantly lower operational costs

This “energy loop” transforms logistics parks into smart microgrids — sustainable, efficient, and future-proof.

9. The Rise of Electric Forklifts in Logistics Parks

Beyond trucks and delivery vehicles, electric forklifts are becoming a cornerstone of modern logistics park operations. As warehouses, distribution centers, and freight terminals digitalize and decarbonize, the shift from internal combustion forklifts to battery-electric forklifts brings significant operational and environmental benefits.

1. Lower Energy and Maintenance Costs

Electric forklifts eliminate the need for diesel or LPG fuel, replacing it with electricity that can be sourced directly from the park’s EV charging and photovoltaic system. Compared with traditional forklifts, electric models offer:

30%–60% lower energy costs

Reduced maintenance (no engine oil, filters, or exhaust systems)

Longer equipment lifespan due to fewer moving parts

When paired with Anengjie Energy’s intelligent charging infrastructure, forklift fleets can be scheduled for off-peak charging during idle hours, minimizing operational downtime and energy expenses.

2. Cleaner and Safer Indoor Operations

Logistics parks often operate large indoor warehouse spaces where air quality and safety are critical. Electric forklifts produce zero tailpipe emissions, significantly improving air quality and creating a safer, more comfortable working environment for warehouse staff.

This makes them ideal for:

Cold chain and food storage centers

Pharmaceutical and e-commerce warehouses

High-density storage facilities

Combined with energy storage systems, forklift charging can also be supported during grid outages — ensuring uninterrupted logistics operations.

3. Integration with Centralized Energy Systems

Modern logistics parks are evolving into integrated energy ecosystems. Electric forklifts, delivery vehicles, and even electric trucks can all share the same charging and energy management network, managed through a unified platform.

Anengjie Energy’s smart charging solutions allow operators to:

Monitor real-time energy demand

Schedule fleet-wide charging sessions

Balance load between forklifts and trucks

Utilice stored solar energy for zero-carbon operations

This unified management not only optimizes power usage but also strengthens the park’s energy resilience and efficiency.

4. A Key Step Toward “Full Electric Logistics”

The electrification of forklifts marks a critical milestone in achieving a fully electric logistics park.

By combining electric vehicles, forklifts, rooftop photovoltaics, and battery storage, logistics enterprises can create a closed-loop energy system that:

Reduces total carbon footprint

Lowers long-term operational costs

Enhances automation compatibility (AGVs and autonomous forklifts)

Strengthens ESG and green supply chain performance

In short, electric forklifts are not just tools — they are part of the broader logistics electrification ecosystem, where energy, equipment, and data are seamlessly integrated for maximum efficiency.

10. The Future: From Fuel Logistics to “Electric + Digital Logistics”

Tomorrow’s logistics competitiveness won’t depend solely on fleet size or warehouse area, but on energy and data capabilities.

Emerging trends include:

Energy management digitalization — AI-driven charging optimization

Vehicle telematics integration — linking fleet data to charging demand

Green supply chain certification — verified zero-emission delivery

CaaS (Charging-as-a-Service) models — monetizing charging as an internal service

These changes define the next era of “energy-aware logistics.” Fleets that control their charging infrastructure will have a permanent operational advantage.

11. Anengjienergy: Empowering the Future of Intelligent Fleet Charging

At the forefront of this transformation is Anengjienergy, a leading EV charger manufacturer and energy integration provider specializing in OEM/ODM and customized solutions for commercial, residential, and fleet applications.

Anengjie Energy’s portfolio covers:

Commercial DC fast chargers (60–1440 kW)

AC smart chargers for fleets and workplaces

Photovoltaic + storage + charging integrated systems

Cloud-based energy management platforms

With its engineering expertise, scalable design, and global manufacturing capacity, Anengjienergy helps logistics companies, real estate developers, and industrial parks:

Build customized fleet charging depots

Implement PV + storage energy systems

Reduce operational costs and emissions

Achieve faster ROI and carbon neutrality

As logistics electrification accelerates worldwide, Anengjienergy’s solutions empower businesses to lead the shift toward clean, intelligent, and profitable logistics operations.

12. Conclusion: Charging Infrastructure Is No Longer a Cost — It’s a Strategic Asset

For logistics parks and fleet depots, Estaciones de recarga de vehículos eléctricos are not expenses — they are profit centers, operational stabilizers, and sustainability enablers.

They deliver:

Lower energy and operational costs

Predictable fleet operations

Faster ROI

Policy and carbon benefits

New revenue opportunities

Stronger ESG and supply chain positioning

In today’s fast-evolving logistics ecosystem, the ability to charge means the ability to compete.

Fleet operators who act early — by investing in dedicated, intelligent, and renewable-powered charging infrastructure — will lead the logistics revolution of the electric age.